Before the beans reach your grinder, there’s a long, unique journey that they go on. We’ve heard the term ‘Farm To Cup’ lots of times, but what does it actually mean? In this article we’re going to break down the initial steps that the beans take, from harvesting, all the way to grinding and brewing.

However, before we look at the processing methods, it’s important that we look at the ‘Farm To Cup’ journey as a whole. Despite how they are processed, all coffee beans share this exact step by step journey.

What does ‘coffee processing’ mean?

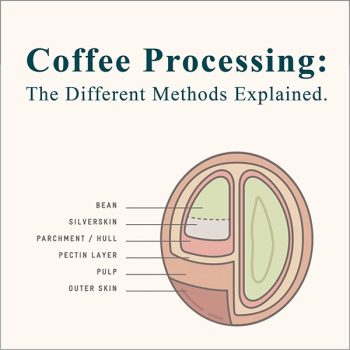

The term coffee processing refers to the series of steps involved in transforming coffee cherries from their original state into the roasted coffee beans you drink at home. The different processing methods can have a significant impact on the flavour and characteristics of the final coffee. The ‘Farm to Cup’ journey typically involves the following stages:

Harvesting:

Once they are ripe, the cherries are picked by hand or by mechanical means. The cherries should be at their peak of ripeness to ensure the best flavour. If the beans are picked too early, this can result in inconsistencies in the roast and a dry, hollow taste. Thankfully this is incredibly infrequent and is usually picked up before export.

Depulping:

The process of removing the outer skin (or pulp) of the coffee cherry. This can be done either mechanically or by fermenting the cherries to loosen the pulp, which is then washed away.

Fermentation:

For some processing methods, once the coffee is depulped, it has to undergo a fermentation stage. The beans are left in water for a certain amount of time, the mucilage starts to break down and impart sweetness onto the beans. Fermentation creates a complexity and adds amazingly unique flavours to the coffee.

Washing:

After the fermentation stage, the coffee beans are thoroughly washed to remove the remaining pulp or mucilage. This step is known as wet processing or ‘washed coffee’. It creates a clean and bright flavour profile.

Drying:

Once washed, the beans are spread out to dry. This can be done by sun drying them on raised beds on patios or by using mechanical dryers. The drying process reduces the moisture level of the beans down to about 10 – 12%

Hulling:

Once the coffee beans have been dried, the outer parchment layer known as the ‘hull’ is removed- this process is known as hulling. This reveals the green coffee beans inside.

Sorting And Grading: The coffee beans are graded according to specific quality standards set by the Specialty coffee industry. Size, shape, colour and density are all looked at during this quality control.

Roasting:

The beans are then exported, either directly or through a broker, to roasteries. Roasting is a complex process that requires precise temperature control and timing to allow the unique flavours and aromas to develop.

Now that we’ve looked at an example of the ‘Farm To Cup’ journey, we’ll now look at the details of each processing method and how they can impact the taste of the coffee.

Washed Coffee

Washed coffee, also known as wet-processed coffee, is a method of processing coffee, it is the most common and widely used method in the coffee industry. The washed process involves several steps to remove the outer layers of the coffee cherry and extract the green beans.

- Ripe coffee cherries are picked from the coffee plants. The outer skin and pulp are mechanically removed, this process separates the beans from the rest of the fruit.

- The depulped beans are then placed into fermentation tanks (water-filled containers) and they are then left to ferment, this usually takes between 12 – 48 hours. During fermentation, naturally occurring enzymes break down the remaining sticky mucilage, this is a honey-like substance that clings to the beans.

- Washing: After fermentation, the beans are thoroughly rinsed with water to remove any remaining mucilage

- Drying: The washed coffee beans are spread out to dry. This can be done on raised beds, patios, or mechanical dryers, depending on the facilities available. The beans are regularly turned and monitored to prevent further fermentation, mould or mildew.

- Washed coffee processing is favoured for its ability to produce clean, bright, and acidic flavours in the final cup. It is often associated with coffees that have a lighter body as it can showcase the distinct characteristics of the coffee’s origin. The washed method is widely used in region such as Central and South America, East Africa, and certain parts of Asia, where it is considered standard practice.

Natural Coffee:

Natural processed coffee is a method of coffee processing where the coffee cherries are dried in the sun or on raised beds without removing the fruit beforehand. It is one of the oldest and simplest methods of processing coffee.

During the natural process, the cherries are sorted to remove any that are damaged or unripe, but the skin and pulp of the cherries are left intact. The cherries are then spread out in thin layers on drying beds or patios, and they are frequently turned to ensure even drying. The cherries are left to dry in the sun for several weeks until the moisture content of the beans is reduced to around 10 – 12%

During the drying process, the sugars and flavours from the fruit pulp infuse into the coffee beans, giving natural processed coffee a distinct fruit and sometimes wine-like flavour profile. The extended contact with the fruit pulp can result in a more complex and intense flavour compared to other processing methods.

Once the beans have dried to the desired moisture level, they are hulled to remove the dried fruit and parchment layer. The beans are then sorted and graded based on size and quality before being packaged and prepared for export.

Natural processed coffee tends to have a fuller body, lower acidity, and pronounced fruit or berry notes. It is often associated with flavours like blueberry, strawberry or tropical fruit.

The taste can vary depending on factors such as the coffee variety, growing conditions and the specific processing techniques used.

Honey Process / pulped natural:

Honey processed coffee, (also known as pulped natural) is a method of coffee processing that sits between the dry and wet processing methods. It is a technique that originated in Central America, and is used in countries such as Costa Rica and Nicaragua, but has recently gained popularity in other coffee-growing regions as well.

During the honey processing method, the coffee cherries are harvested and sorted, just like in the other methods.

However, instead of removing the skin and pulp of the fruit completely (as in wet processing) or leaving the entire cherry to dry (as in dry processing) the outer skin is removed, but a portion of the sticky mucilage, which is similar to honey in texture and colour, is intentionally left on the coffee beans. The sticky layer is responsible for giving honey processed coffee its name.

Once the outer skin is removed, the coffee beans are spread out on drying beds or patios to dry. The beans are turned periodically to ensure even drying. As the beans dry, the remaining mucilage ferments and imparts flavours onto the coffee.

The duration of drying can vary, with different levels of mucilage left on the beans, resulting in different honey processing classes such as yellow, red, black and white. The colour refers to the amount of mucilage left on the beans.

Honey processed coffee is known for its unique flavour profile. It often exhibits a balance between the sweetness of natural processed coffee and the cleanliness of washed coffee.

The fermentation of the mucilage during drying can contribute to flavours that range from fruity and floral to caramel-like and chocolatey.

The resulting cup of honey processed coffee can have a rich, full-bodied taste with a smooth mouthfeel and a distinct sweetness.

Coffee enthusiasts appreciate honey processed coffees for their complexity and the ability to highlight specific flavour characteristics of the beans.

However, since the process involves fermentation, it requires careful monitoring and control to prevent over-fermentation or spoilage. Therefore, honey processed coffees tend to be produced in smaller quantities and are often considered specialty coffees.

Anaerobic Fermentation

Anaerobic fermentation refers to a method of coffee processing that involves fermenting the coffee beans in an oxygen-free (anaerobic) environment.

This process is typically carried out after the coffee cherries have been harvested and the outer fruit layers have been removed.

During anaerobic fermentation, the coffee beans are placed in sealed tanks or containers, often with added water and allowed to undergo fermentation for a specific period of time.

The absence of oxygen in this process creates an environment that promotes the growth of specific microorganisms, which can have an impact on the flavour and aroma of the coffee.

The duration of the fermentation can vary depending on the desired outcome and the specific characteristics of the coffee beans.

It can range from a few hours to several days. The beans are regularly monitored during fermentation to ensure that the desired flavours and attributes are achieved.

Anaerobic fermentation can result in unique and complex flavour profiles in coffee. The absence of oxygen alters the biochemical reactions that take place within the beans during fermentation, leading to the production of different compounds.

This can result in flavour that are fruity, wine-like or even reminiscent of fermented beverages such as kombucha.

The popularity of anaerobic fermentation in coffee processing has grown in recent years, as it offers coffee producers an opportunity to experiment with different flavours and differentiate their products in the market.

Coffee connoisseurs and specialty coffee enthusiasts often seek out anaerobic fermentation coffees for their distinctive taste experiences.